SwitchWeld

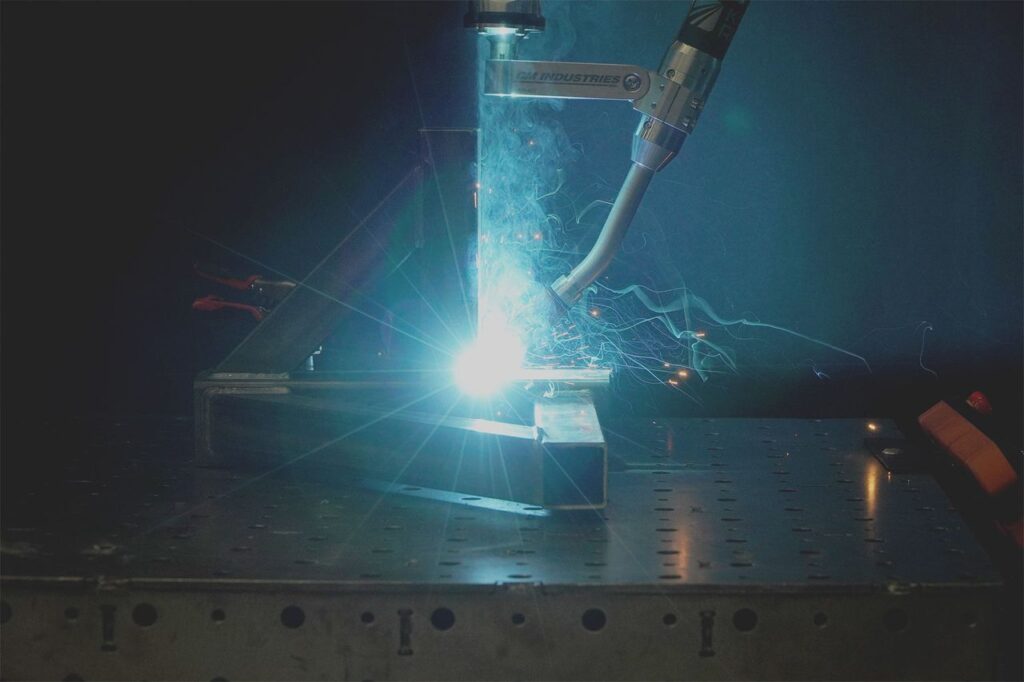

The Future of Welding Automation

Finding It Tough To Meet Demand?

- Labor shortage is affecting everyone.

- Sadly, the problem will not be solved anytime soon.

- However, demand for excellent fabrication grows every day

- The backlog grows, and so does the overtime for metal workers

As the older generations begin to retire and the younger generations enter other traders, manufacturers have to adapt.

Works With The Welders You Have

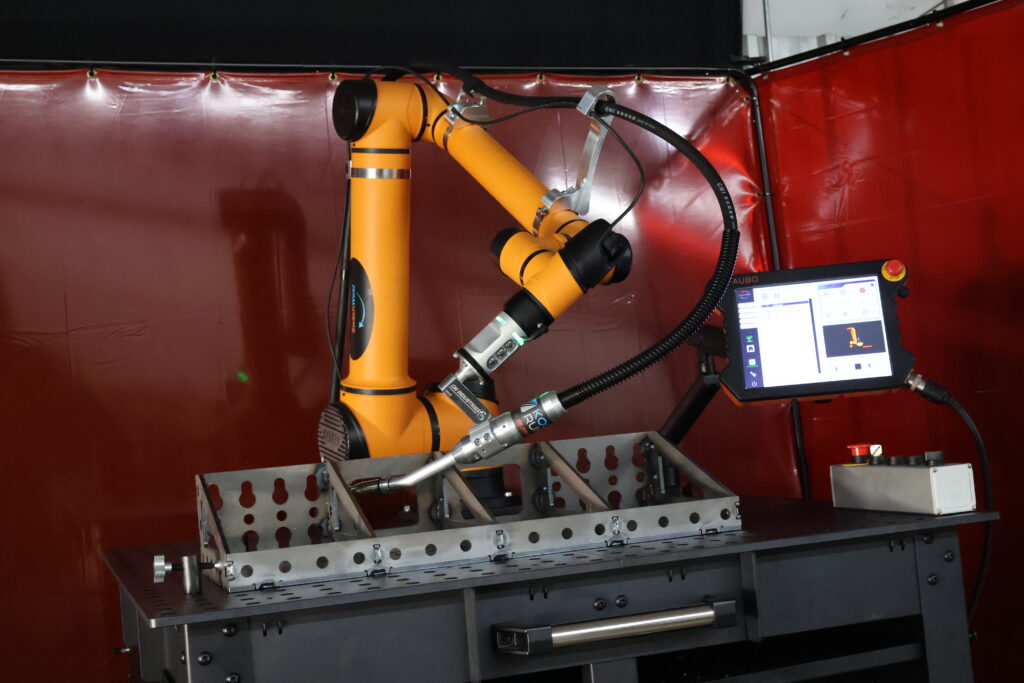

Your welding team moves the needle of your business. SwitchWeld cobots can help them drastically improve productivity by focusing on the production, rather than the programming.

SwitchWeld makes cobot programming simple, allowing every member of your team to program the cobot by themselves. SwitchWeld empowers your existing metal workers and welders, helping them scale their talents more than ever.

Ready For Production In Minutes

Our cobot solutions, powered by SwitchWeld, have the fastest setup times on the market, allowing you to quickly teach the cobot a new welding sequence. This makes automated small-batch production extremely efficient.

An operator can have the cobot producing in minutes, allowing for quick and easy welding all day long.

Higher Productivity. Higher Quality. More Customers.

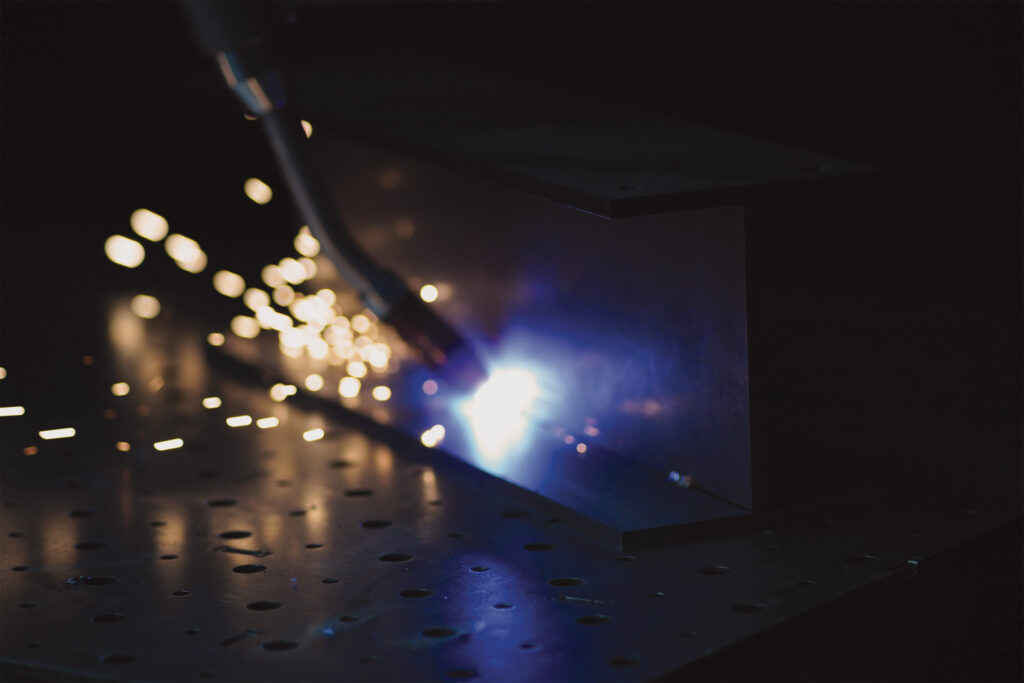

Our cobot efficiency and welding accuracy let you skyrocket productive AND reduce rework due to human error. The cobot production quality and speed are in a league of their own.

Our cobots help you get more business and give you the capacity to handle it and more. Keep your production costs low without compromising quality.

Why Choose SwitchWeld?

High Quality Components

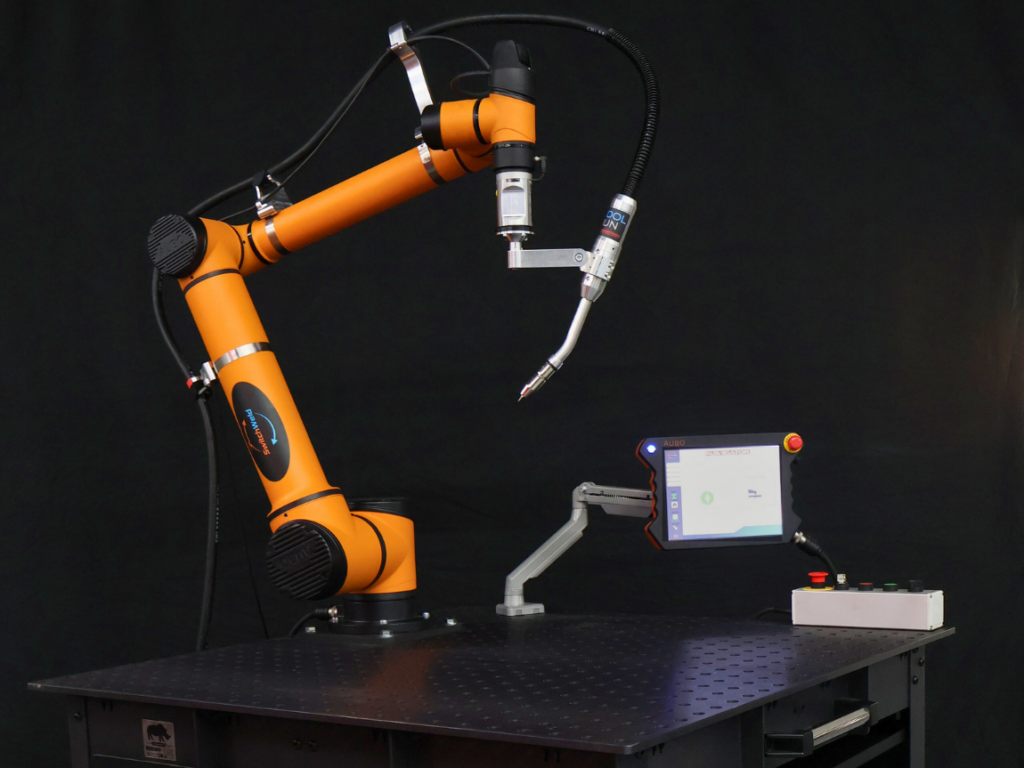

Our system is built on a top-tier cobot arm introduced in 2014 and perfected for welding since 2016.

User-Friendly Design

Designed specifically for welders, SwitchWeld offers intuitive controls and quick setup, allowing operators to be up and running in about two hours.

Precision and Control

Our joystick provides precise control for the best welds, ensuring high quality motion and positioning.

Cost-Effective

SwitchWeld is competitively priced, offering the best value in the industry.

Top-Tier Motion

SwitchWeld’s motion is the best in the industry, allowing for the best lines, curves, circles, and weaves, with great speed control.

The SwitchWeld Family

SwitchWeld Basic

- Most affordable option

- Ideal for those who already have a welding table and power supply.

- Includes the cobot, end-effector, robotic torch, user interface pendant, and job box.

SwitchWeld Plus

- Premier solution that includes everything you need for a complete welding setup.

- Features the cobot, end-effector, robotic torch, user interface pendant, job box, a 4×4 welding table and a Miller DeltaWeld power source.

- Configuration is perfect for those who want an all-inclusive package to start welding right away.

SwitchCut

- A versatile solution that starts with SwitchWeld Basic but is specifically set up for plasma cutting.

- Users can easily switch between welding and plasma cutting, adding significant value and flexibility to their system.

Key Features

Joystick

Programming

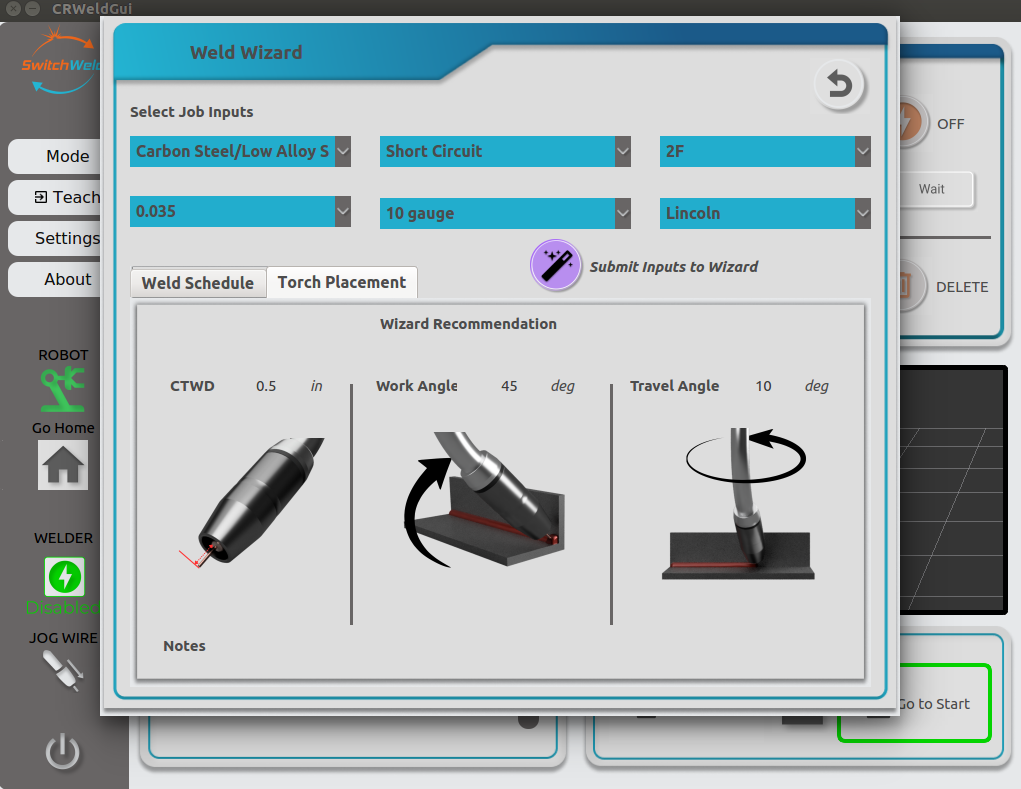

Arc Advisor

Our joystick provides you the precision and control for making great welds. Handling a cobot has never been easier.

Your one-stop shop for setting up your welds. Our program makes the programming quick and easy for you with high customizability.

Our innovative ArcAdvisor feature takes the guesswork out of welding. By calculating the best welding parameters from a vast database, it ensures consistent, high quality welds every time.

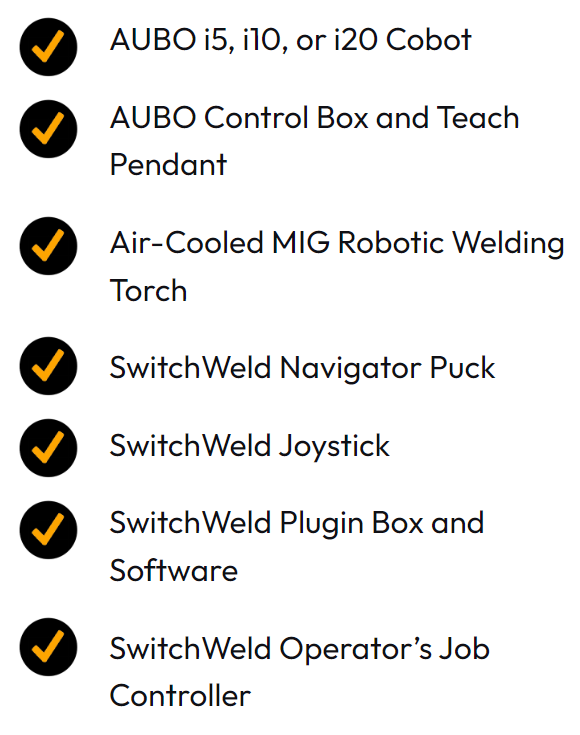

What’s Included

How It Works

Simplify Your Welding Process

Setup

Unbox your SwitchWeld system and connect it to your existing welding tools and power supply.

Program

Use the end-effector puck to point, arc, and orient the cobot by hand. The joystick allows for the precise control needed for great welds.

Weld

With the intuitive interface and ArcAdvisor, start welding with optimal settings calculated specifically for your project.

Applications

The SwitchWeld is versatile and reliable, making it ideal for a wide range of applications:

- Shipbuilding

- General Manufacturing

- Civil Structures

- Custom Metal Fabrication

Testimonials

“And…the joystick…I think, was a gamechanger on our end. Instead of trying to two-hand the whole thing around, they were able to fine-tune it in with the joystick on the end. Extremely simple.”

“Easy to use machine. Good, consistent welds. We’ve had a couple of decent sized frame jobs that came through with tubing. Extremely nice.”

“The installation, setup, and training took only four hours. And keep in mind, this company had no previous robot experience, we had a half a day of training…It went phenomenal.”